SuperSense provides high quality, durable temperature measurement products for the air-conditioning, refrigeration, warehousing and transport industries.

Manufactured in Australia by the SuperCool Group of Companies, the SuperSense range includes a selection of NTC and PTC probes and sensors, alongside the newly developed SMARTprobe and SMARTware™ product temperature simulation solutions.

This technology has been developed from the many years of experience within the SuperCool team and testing at its world class SuperTest research and development centre in Brisbane.

SuperSense SMARTprobe and SuperSense SMARTware™ respectively provide hardware and software capabilities to deliver product temperature simulations that mimic the temperature of any pre-determined product.

The cold chain industry benefits from SuperSense technology because it enables timesaving, simplified processes that both improve temperature compliance and reduce the risk of food or product loss.

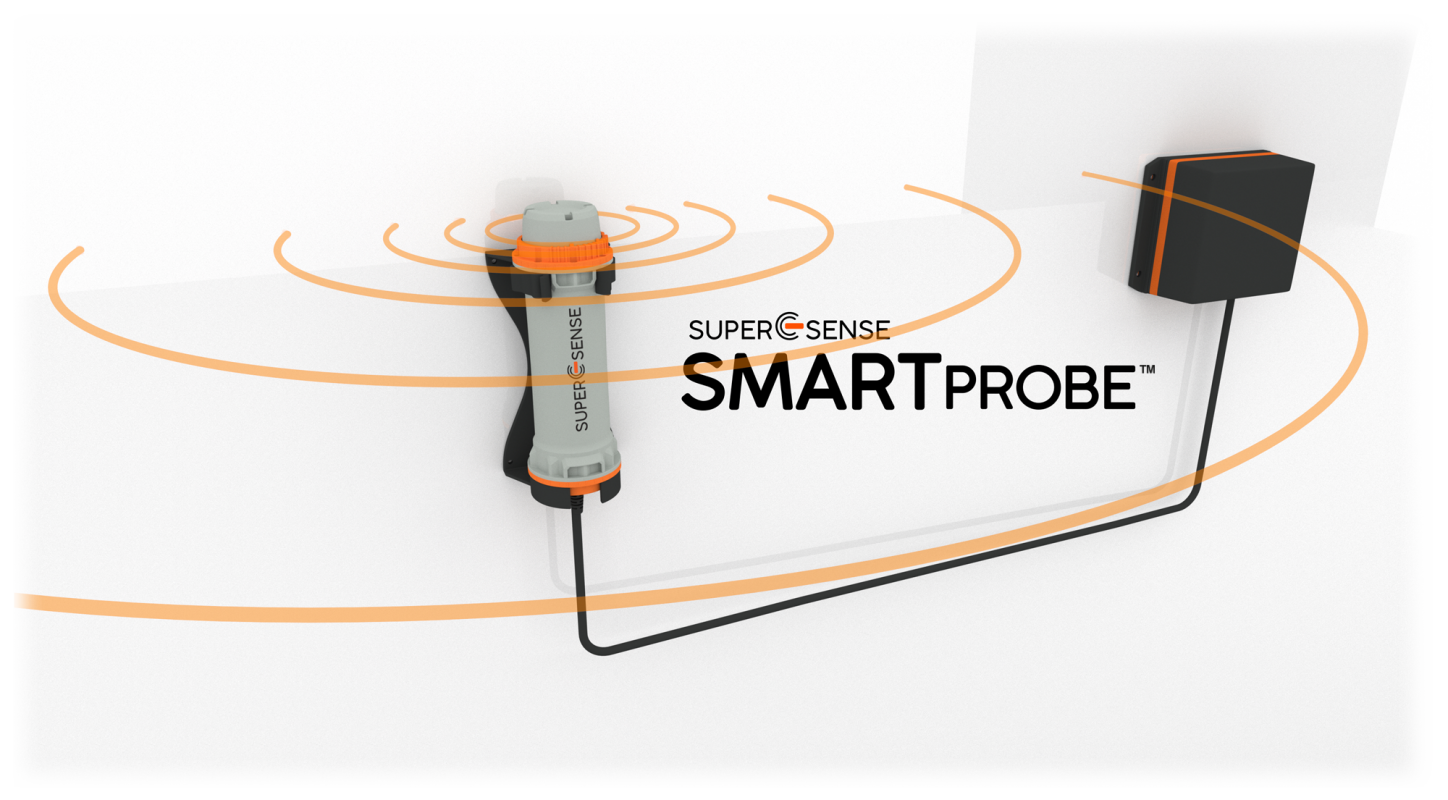

SuperSense SMARTprobe™ is a food product temperature device that eliminates the necessity to insert temperature sensors and thermometers into chilled or frozen goods for the purpose of measuring core temperature information. It is a quick plug-in hardware device suitable for connection to most leading temperature monitoring systems without the need for additional software and can be calibrated to suit a wide range of food products.

Read more.

SuperSense SMARTware™ is a program that calculates the temperature of food products in various environmental and refrigerated conditions. There is no hardware required, and its function is based on inputting information from the ingredients shown on the manufacturers' data sheet or packaging of the food product.

The software allows food companies to plan and predict the impact of temperature fluctuations and abuse on products in the cold chain. It is an essential tool for auditors, food designers and food packagers.

Read more.

Quality management systems in the transport and storage of food in the cold chain should comply to the principles of HACCP. To achieve this, it is necessary to harness temperature data and information to reflect the critical points in the cold chain process, and to manage them accordingly.

The modern cold chain has expanded extensively in recent years with more food stored under refrigeration every year, and food is being transported over longer distances. Consequently, it is increasingly difficult for quality control and transport personnel to manage critical points in the cold chain, particularly when it comes to temperature management.

Ambient and refrigerated space air temperatures cannot be relied on to reflect accurate food product temperatures at these points, and it is only by knowing the actual core temperature of the food product, that a safe quality decision is possible for its delivery.

Read more