The SuperSense Smart Solutions product range was developed by SuperCool Asia Pacific, a member of the SuperCool Group of Companies. The products reflect the company mission to provide advanced and innovative solutions to the cold chain industry.

One-third or more of the food produced each year globally is never eaten. As a result of wastage, poor management of food transport or lack of refrigerated transport, 800 million people are chronically undernourished and one in eight children go to bed hungry every night. Yet the world currently grows and produces enough food to feed the entire planet.

Food wastage globally has reached such a critical level, that all participants in the cold chain must accept responsibility for ensuring accurate compliance to standards that will ensure that food is always kept at temperature.

However, operators in the food cold chain are finding it increasingly difficult to keep pace with price pressures, long distances and rising costs to deliver refrigerated food faster and in larger quantities. These influences impact on the quality of food production and delivery, and whether food can be guaranteed to be at the right temperature at all times.

SuperSense Smart Solutions provide operators in the cold chain with a simple and effective means of measuring food product temperatures continuously across the cold chain. By doing this, the quality and safety of food items can be assured, guesswork and finger pointing is removed, food loss and wastage is reduced and savings in time and money are achieved.

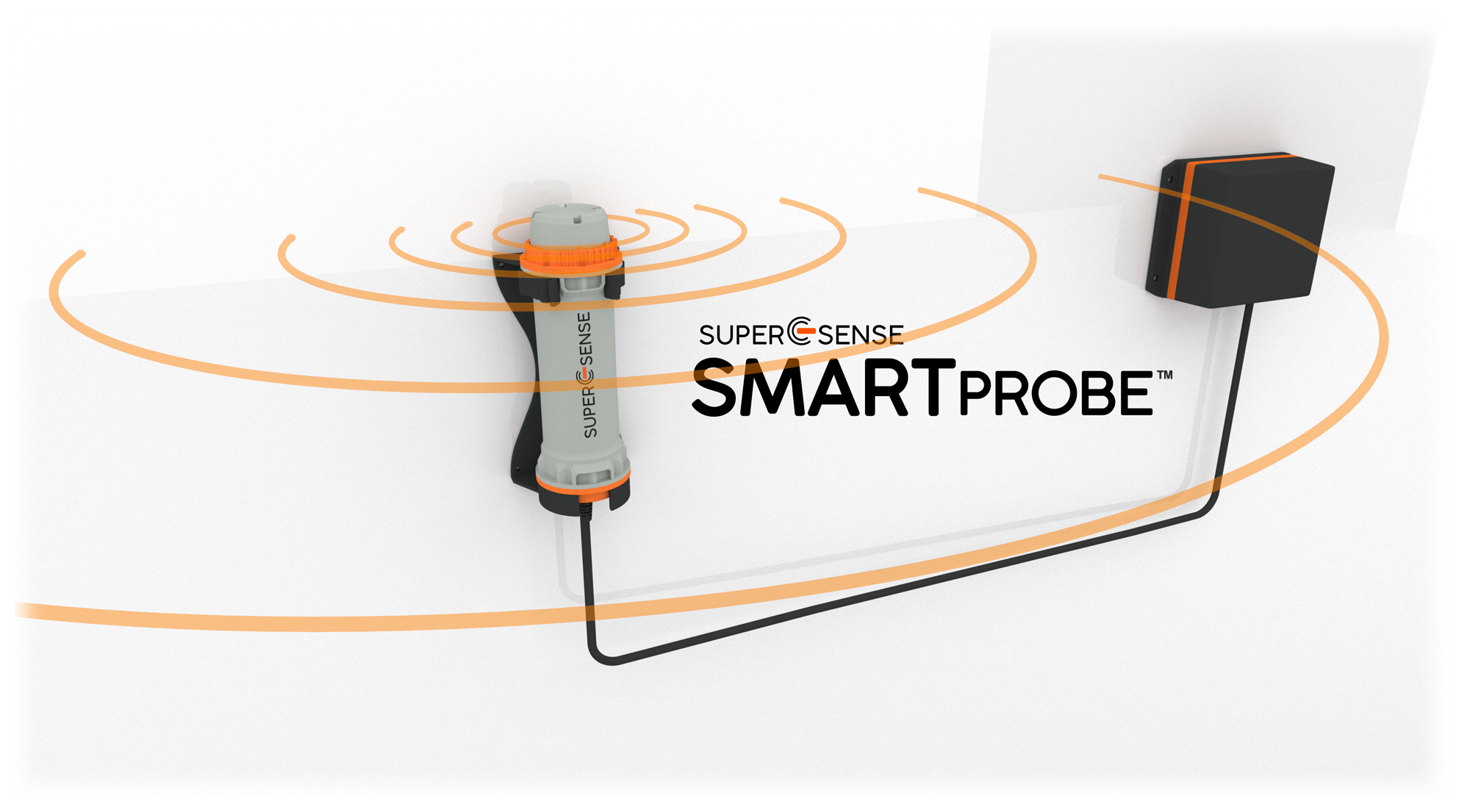

SMARTprobe™ is a temperature sensor integrated into a unique housing with thermal properties that can be tuned to match the properties of the goods being transported or under refrigerated storage. It allows companies to accurately determine the temperature of the actual products as opposed to simply measuring air temperature, or relying on pocket thermometers and cheap quality data loggers which can be unreliable and inaccurate.

SMARTware™ is a separate software program that allows food companies to plan and predict the impact of temperature fluctuations and abuse on products in the cold chain. It is an essential tool for auditors, food designers and food packagers to help identify bad spots in the cold chain where temperature abuse occurs. Conversely, it can be used to validate a process considered to have no bad spots or temperature critical points.

The program calculates the temperature of food products in various environmental and refrigerated conditions. There is no hardware required, and its function is based on inputting information from the ingredients shown on the manufacturers' data sheet or packaging of the food product.